Not all fats are the same

Fats are particularly interesting as energetic upgrade of rations. Especially in stressful situations (e.g. heat) or phases of high performance (e.g. early lactation), it is important to ensure adequate energy supply despite reduced feed intake, without disturbing ruminal function. In case of energy shortage, important body reserves are depleted. A strong mobilisation of body fat has negative effects on animal health and thus on performance.

The solution: rumen-stable fats. They do not impair the microbes as they are not metabolized in the rumen and reach the abomasum unaltered. The digestion occurs in the small intestine.

When using rumen-stable fats, however, it is important to know their special properties.

Because: not all fats are the same!

Products on the market differ significantly in terms of the fatty acid pattern, the manufacturing process and thus also in terms of rumen stability and digestibility.

Saponification vs. fractionation, hydrogenation

Saponification

The oldest production method for rumen-stable fats is saponification. Fatty acids, as by-products from the refining process, are mixed with calcium or sodium. During saponification, protection from microbial attacks is generated through the esterification with calcium or sodium. This process depends on the pH-value. A reliable rumen-stability is only possible at a pH-value of over 6.5. Under acidic conditions, the soap structurally decomposes back into its smaller components, as fatty acids and calcium or sodium. The free fatty acids are then non-stable and can influence ruminal microbes.

A higher proportion of concentrated feed in the ration can, at least temporarily, lead to lower pH values. Under such conditions the rumen stability of soaps is no longer given.

Fractionation, hydrogenation

Improved processing in the production of rumen-stable fats is possible through the reduction of the proportion of unsaturated fatty acids and an increase of the proportion of saturated fatty acids (especially C16:0 and C18:0). Vegetable oils based on C16:0 and C18:0 have a typical melting point of above 50 °C. This means that in solid form, under standard outside temperatures they are rumen-stable. Rumen-stable fats, with high melting points, are only digestible for cows when delivered in powder form.

The reduction of the proportion of unsaturated fatty acids can be reached through two different processes:

1. Fractionation = separation of the saturated and unsaturated fatty acids

2. Hydrogenation = saturation of the double bonds

A complete reduction of the unsaturated fatty acids can only be achieved through hydrogenation. We only use hydrogenated fats for the production of out fat powders BEWI-SPRAY® RS 70 and BEWI-SPRAY® 99 M.

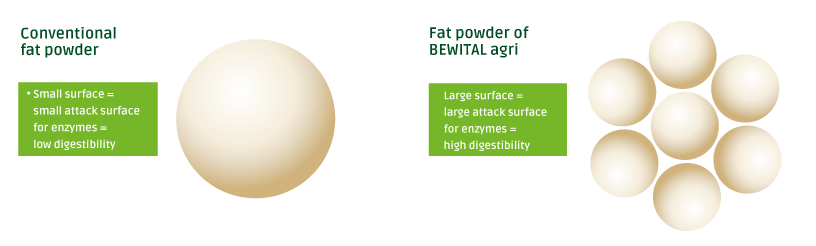

Particle sizes decides on digestibility

The digestibility of fat powders depends highly on structure size and surface of their particles. A reduction in particle size leads to an increase of surface in relation to mass.

A surface increase thus leads automatically to an increase in surface area that can be utilized by lipase bacteria in the digestive tract. This increases digestibility.

C16:0, C18:0 – or both?

Rumen-stable fats are primarily based on palm- or rapeseed oil. The resulting products differ significantly in their fatty acid pattern. The proportions of palmitic acid (C16:0) or stearic acid (C18:0) are crucial.

Palmitic acid (C16:0) and stearic acid (C18:0) differ in their effect on the dairy cow’s metabolism. There are also differences regarding lactation stage and performance level.

Palmitic acid (C16:0)

Palmitic acid (C16:0) is used as a lipogenic fatty acid primarily to build up milk or body fat. The inclusion into milk fat is limited in its quantity. Under the conditions of negative energy balance, this leads to an accumulation in liver fat, since in this phase there is no build-up of body fat but rather a mobilisation of body fat.

De Souza et al. (2019) showed that the use of products rich in palmitic acid (>80 % C16:0) with 1.5 % C16:0 in the total dry matter of the ration even increased the negative energy balance at the beginning of lactation. This could explain the negative effects of long-term, excessive use of products rich in palmitic acid during the first half of lactation, being described several times. The use of a mixture of palmitic acid and stearic acid (46 % stearic acid) with a 2 % proportion in the DM resulted according to Piantoni et al. (2015), on the other hand, in an improved energy intake at the beginning of lactation, reduced negative energy balance and reduced body mass losses. This shows the need to limit the amount of palmitic acid during early stage of lactation.

Products which are rich in palmitic acid (> 80 % C16:0) should only be used limited or not during early lactation, in order to avoid negative effects on the metabolism (attention: risk of fatty liver!).

Stearic acid (C18:0)

Stearic acid (C18:0) can be metabolised for energy production in the liver even before calving as well as during early lactation, in contrast to palmitic acid (Loften et al., 2014). The use of a product rich in stearic acid (>90 % C18:0) with 2 % in the dry matter according to Piantoni et al. (2014) showed an improvement in dry matter intake (26.1 kg/day vs. 25.2 kg/day) as well as milk yield (40.2 kg/day vs. 38.2 kg/day). The concentration of milk ingredients was not influenced, but the daily amount of milk fat and milk protein increased. The BCS and body mass development were not influenced by the stearic acid supplementation. The increase in dry matter intake and milk yield was even higher in high-yielding (>50 kg/d) compared to low-yielding cows (<40 kg/d).

CONCLUSION: The right mix of C16:0 & C18:0 makes it work!

The studies show that the use of stearic acid-rich products such as BEWI-SPRAY® RS 70 (> 90% C18:0) or BEWI-SPRAY® 99 M (54% C18:0 / 44% C16:0) is particularly beneficial during early lactation to improve energy supply and reduce negative energy balance.

In our video you can find out more about the advantages

and possible uses of rumen-stable fat powder

Our solution:

BEWI-SPRAY® RS 70 oder BEWI-SPRAY® 99 M

With our rumen-stable fat powders BEWI-SPRAY® RS 70 or BEWI-SPRAY® 99 M you can supplement the ration on different raw material bases (rapeseed or palm oil).

With an application rate of 200-500 g / animal and day, it is possible to increase energy density in an optimal way.

Rumen-stable fat powder based on rapeseed oil

Rumen-stable fat powder based on palm oil